About E-care manicure

The Concept of Manufacturing ECARE Manicure Burs :

G.O.S(Global Operation System ) of ECARE is a system with LEAN PRODUCTION.

It is excellent, correct and delicate.

For users, it is profitable and efficient.

Thoughout all the manufacturing system, we produce and control by the standard of ISO 13485.

ISO 13485 is a standard of controlling medical equipment quality.

It includes all the standards of ISO 9001 and other specific requirements of medical equipment.

.png)

Craftsmanship of ECARE Manicure Burs:

Shank of ECARE:

1. Every shank processes overheating and tempering.

The strength of bending resistance keeps in HRC40-45°.

2. Throughout the centerless grinding, we make sure the whole shank out of roundness<0.005mm.

3. Fit the International Standard Tolerances : EN ISO 1797:2017 Shanks for Rotary

and Oscillating instruments.

4. We have two kinds of shanks of alloy-steel burs, SHP and HP.

Due to the two different lengths, we decided the length from the needs of manicurists.

We have the instrument to make sure that the shank can meet the only conditions, accuracy.

The Working Parts of ECARE:

The Set of Super Alloy Steel:

1. The Hardness of The Material ≧ HRA 89°

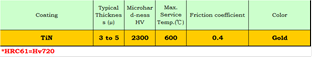

2. The Special Coating of Surface:

-The lifespan would be three times longer.

-The heat radiation is very excellent.

.png)

.png)

The Set of Coating-dia:

1. The Hardness of The Material ≒ 98.59 Gpa

2. We use the special composite coating-dia layer formula

with the sharpness of high-speed-using and the characteristics of low-speed-grinding.

The Set of Stone:

1. The Mohs Scale of Mineral ≒ 9

2. Actuarial granularity(µm) will maintain the sharpness of high-speed-using

and the characteristics of low-speed-grinding during manicuring.

The Set of Brushes:

Three Kinds of Natural Hair: Pig Hair/ Horse Hair/ Wool

HR Group

E-mail: service@hannru.com

TEL : 04-7777213